About Delios

DELIOS - YOUR SAFETY, OUR PRIORITY

Dedicated to premium quality & performance with a mission for continuous development through innovation & design

Delios began primarily as an aerospace engineering company in Melbourne Australia, which after popular demand by track customers developed & evolved into an automotive disc brake rotor manufacturer. Not happy to just run with the pack, we focus a vast amount of our resources into developing and maintaining a braking program that’s in a league of its’ own.

We offer the personal touch of a family controlled business; focused on quality products, integrity, friendly service and timely delivery.

Utilizing over 20 years aerospace engineering knowledge & experience to research, design & develop brake discs for the automotive aftermarket. Delios brake rotors consist of a proprietary premium quality metal casting that is carbon enhanced and grain refined in addition to a unique manufacturing process to increase thermal resistance, performance & optimise endurance.

Over the years Delios has made its mark and continues to vastly expand in the automotive aftermarket industry as a high quality & innovative braking component manufacturer.

This remains our primary focus, we will only deliver the best of which is expected of Delios Brakes to our customers.

Every stage is researched, developed & engineered to meet our strict guidelines & criteria.

Carbon Advantage

The highest quality raw materials are used to make our propriety casting formula. A high carbon formulated cast iron used for all our premium brake disc. The 'Carbon Advantage' formula was designed with special wear resistance and noise deadening properties ensuring a high level of thermal stability. This material is poured into specially designed moulds and post treated to give stress reduction and an even grain matrix. Tested on the track to exceed temperatures of 800 degrees.Symmetrex

Mould Technology- ‘Rho-bust’ venting specifically designed for different models & brake applications enhancing strength & stability, as well as improving cooling efficiency. Unique designs such as Rhombus pillar design geometry and multi fork splayed design ensure strong stability in high temperature situations.Advanced Machining Process & Technology

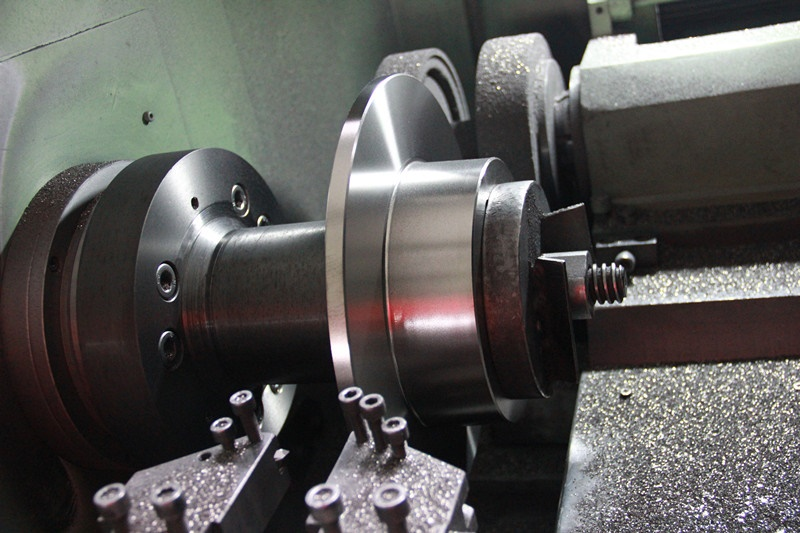

The highest quality castings are used in the machining process where a combination of the latest CNC applications are used to cut all the specific geometry to tolerances of less than 13 microns, and surface finishes as little as 1 micron. The greatest care is taken to ensure minimum stress on the casting. All our rotors are dynamically balanced. This is all performed in a Lean, Best Practices environment. Allowing us to focus on research, development and process techniques.Design & Slotting Process

All patterns are specifically designed & custom slotted to each disc rotors’ exact measurements (including thickness) & specifications. Designed and Engineered then rigorously tested on the track and in harsh conditions and to ensure that each design further enhances stability, performance & heat dissipation. With over 30 different designs for all different makes, models & brake applications- you will see and feel the difference.Pro-tekt

A proprietary coating formulation based on a time tested military corrosion preventative process. It is a superior highly corrossive resistant coating that is environmentally friendly and its’ durability is not limited by heat. Pro-tekt™ coating is also ceramic pad approved and will not contaminate your brake pads. Many other paints or coatings will flake or burn at high temperatures- Pro-tekt ™ is specially formulated to allow heat to dissipate from the rotor and will never flake or burn, which translates to more corrosion endurance for your brakes.